Additional Info

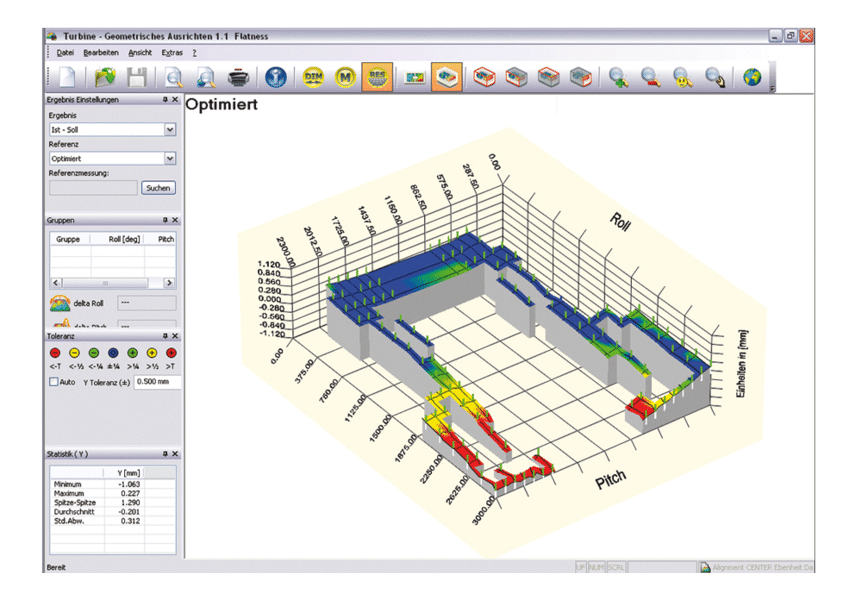

PRÜFTECHNIK Alignment Systems is the leading specialist in precision laser alignment. Their high-tech measurement systems are used by leading industrial organizations worldwide. Use ALIGNMENT CENTER, the common PC software platform for all PRÜFTECHNIK Alignment instruments and applications, to manage your measurement files and related data. It provides you with the perfect solution for preparing, analyzing, organizing and archiving your measurement files. All alignment and measurement specifications including thermal growth compensation, alignment presets and tolerances are saved for future use. The software can also be used to generate professional colour reports. The two-way communication feature within the software is used to transfer files to and from the instrument. It supports shaft, bore and geometrical alignment applications, and the following instruments: ALIGNEO, OPTALIGN smart, ROTALIGN Ultra, ROTALIGN PRO, BORALIGN, ROTALIGN, NOVALIGN, OPTALIGN PLUS Series, smartALIGN. Utilizing ALIGNMENT CENTER improves efficiency.

Set-up

- Create user-specific templates to suit the measurement job

- Set up file information to include file and user names, company, plant, area and machine train

- Prepare file in advance on a PC and transfer to the instrument via the two-way communication

Analyze

- Display results in either 2-D or 3-D graphics depending on the application

- Evaluate results using the measurement table

- Customize measurement reports to include company information and logo

- Simulate measurement results by entering manual values

- Optimize alignment by redefining fixed feet

- Customer-defined tolerances

- Edit dimensions

Archiving

- Create a backup of your measurement files

- Restore files saved in the backup

- Organize files in a tree structure with an unlimited hierarchy

- Any type of document can be stored in the tree structure

- Comprehensive database search

- Ability to import and export data

- Management of measurement files and

The latest ALIGNMENT CENTER software update, version 2.3, offers:

- Shaft measurement modes intelliPASS and intelliPOINT support

- Shaft measurement modes: support of “rotating arm” and “180 degree” measurement of cardan couplings

- Shaft cardan coupling calculator for vertical offset and articulation angle

- User defined non-symmetrical vector tolerances for shaft measurements

- Straightness measurement modes: support of “bore and spindle” measurement

- Bore axial result view

- Bluetooth connection/communication with ROTALIGN Ultra iS computer

- ROTALIGN Ultra iS firmware 3.03 update

- Improved management of history labels

- Improved bore polar analyze view

- All applications: numerous bug fixes and improvements