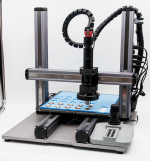

Presenting the Automated Microscopic Particle Counter from Yellotec

Yellotec is proud to present their in-house designed and constructed Automated Microscopic Particle Counter (AMPC) which measures solid particulate contamination of liquids to control the cleanliness of used and new oils. Ultimately increasing equipment life and availability of all lubricated assets. Will measure accurately the results of the Oil Sample Analyzes by removing Human Error and Outside influence from the measuring

Utilizing RDI’s Motion Amplification Technology, Yellotec has the capability to detect structural and vibrational malfunctions in machinery. By eradicating such problems, the expenses incurred due to subsequent breakdowns and idle time can be minimized, and plant productivity enhanced!

Allow us to offer you similar benefits!

Why the AMPC is the ideal instrument for Oil Analysis

The Automated Microscopic Particle Counter is the ideal Oil Analysis Instrument that every plant needs due to its Versatility in Analyzing Different Oil Samples. As well as the ability to operate the instrument with full automated and Minimal User Interactions. Meaning that Human Error is not a factor when completing the analysis of the oil sample.

The AMPC technology has been designed so that it limits the interference of Moisture and Air during the Analysis, therefore, leading to zero influence over the count

The Typical Oil Samples that can be tested with the Automated Microscopic Particle Counter are as follows:

- Hydraulic oils

- Turbine oils

- Automotive and Industrial Gear oils

- Engine oils

- Water-based hydraulic fluids

- Phosphate ester-based hydraulic fluids

- Fuels

- Coolants

The Custom Yellotec Developed Particle Analysis Software ensures accurate and repeatable results even when the particulate contamination of the oil is high

The Benefits of the Automated Microscopic Particle Counter

Are you looking for a guaranteed Particle Counter or Consider adding the AMPC to your Plant Monitoring or Machine Condition Monitoring Equipment? We have put together a list of Benefits of choosing the AMPC

- The AMPC has the capability to analyse up to 25 sample filter grams at fully automated.

- The AMPC instrument and software were developed in-house to analyse used oils with contamination levels as high as ISO 4406 count of 24/23/22.

- Results are automatically saved in a database file format which allows them to be imported into any LIMS system.

- It is as simple as – Load samples, entering the batch number, pressing count and walking away.

- System auto focuses before every image is taken to maximise particle recondition for accurate sizing and counting of particles.

- The system can be set up to accommodate 25mm and 47mm filter gram patches.

- No intensive training is required to operate the instrument. Save time by being fully automated.

- Multi-levels of access can be set up to protect the configurable settings during routine operation

- Licensing fee with updates on software included in the purchase price.

- Robust design and well-built.

AMPC characteristics

- High-resolution digital camera.

- Automatic Particle recognition and sizing using Yellotec-developed propriety software.

- The system allows four fully calibrated particle sizes and measuring

- Fully automated X, Y, and Z sample stage (25 sample capacity).

- Optically magnification Microscopic stage

- LED light source for sample illumination.

- Yellotec developed particle analysis software capable of recognizing and measuring wear and contamination particles for separate reporting purposes.

- External joystick to manipulate the microscope when in manual mode

- High-spec workstation PC with 24″ Monitor.

Contact Yellotec

For more information on this article or AMPC, feel free to contact us.

Yellotec is one of the leading suppliers of the most effective and efficient technology in machine health and reliability monitoring equipment in Africa. As well as providing services that help plant and equipment managers predict all failures as well as prevent major failures in the future.

For expert advice and the latest in machine reliability technology Please feel free to contact us either by Contact Number, Email, Contact form or Visit us.

"*" indicates required fields