Specifications

What is Particle Measuring Technology?

Particle measuring technology is used to control and monitor the cleanliness of used oils and to identify quality deficiencies and excessive wear in order to avoid costly machine failures.

Why the AMPC is the ideal instrument for Oil Analysis

The Automated Microscopic Particle Counter is the ideal Oil Analysis Instrument that every plant needs due to its Versatility in Analyzing Different Oil Samples. As well as the ability to operate the instrument with full automated and Minimal User Interactions. Meaning that Human Error is not a factor when completing the analysis of the oil sample.

The AMPC technology has been designed so that it limits the interference of Moisture and Air during the Analysis, therefore, leading to zero influence over the count

- Minimal user interactions are required to operate the instrument

- Fully Automated.

- The technology used produces the most accurate particle counts as no interference from moisture and air trapped in the sample influences the count.

- The algorithm programmed in the software ensures accurate and repeatable results even when the particulate contamination of the oil is high

The Benefits of the Yellotec AMPC

Are you looking for a guaranteed Particle Counter or Considering adding the AMPC to your Plant Monitoring or Machine Condition Monitoring Equipment? We have put together a list of Benefits of choosing the Fermion C1

Affordable :

- Affordability: When running a business, you want to be as cost-effective as possible, this is why when designed the Fermion C1, we tried to keep it as affordable as possible

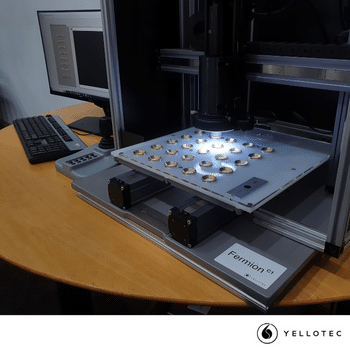

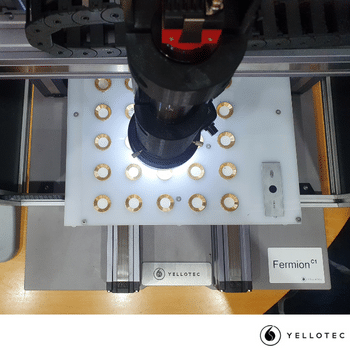

- AMPC has the capability to analyse up to 25 sample filter grams fully automated.

- This instrument and software were developed in-house to analyse used oils with contamination levels as high as ISO 4406 count of 24/23/22.

- Results are automatically saved in a database file format which allows it to be imported into any LIMS system.

- It is as simple as – Load samples • Enter the batch number • Press count and Move on to your next task • Return when it is done and view the accurate results

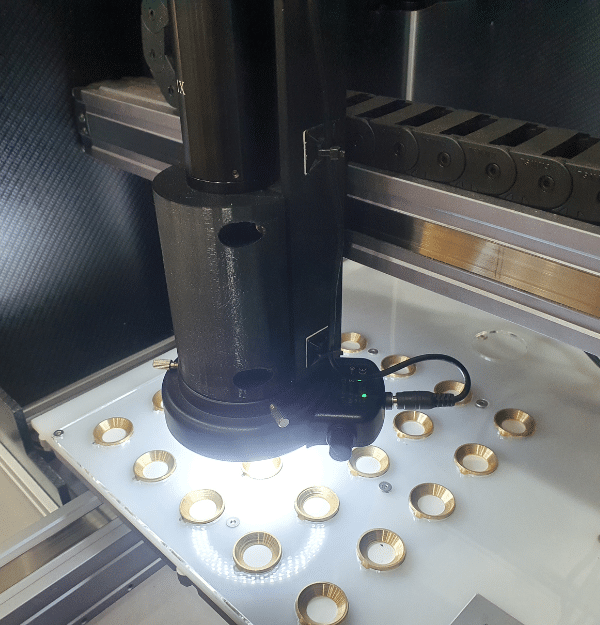

- The system auto-focuses before every image is taken to maximise particle recondition for accurate sizing and counting of particles.

- The system can be set up to accommodate 25mm and 47mm filter gram patches.

- No intensive training is required to operate the instrument.

- Save time by being fully automated.

- Multi-levels of access can be set up to protect the configurable settings during routine operation

- Licensing fee with updates on software included in the purchase price.

- The Fermion C1 has a Robust design and is well-built.