Additional Info

Quick Setup

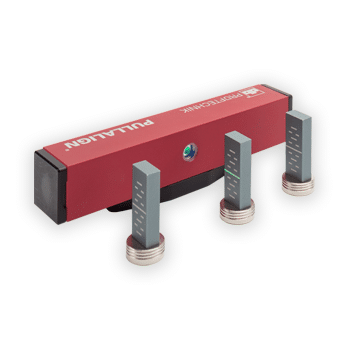

PULLALIGN Lite 2 is securely mounted onto the pulley with a magnet

Height Adjustable Targets

The targets can be easily adjusted in height to display a perfect alignment result

Green Laser Beam

High visibility on the targets even in very bright indoor and outdoor light conditions

PULLALIGN benefits

- Efficient one-man operation

- Shows offset, vertical and horizontal angle simultaneously

- Reflected beam technology doubles the distance, enhancing accuracy

- Only one laser for complete alignment

- Reduces down time and energy costs

- Reduces vibration and belt noise

- Prolongs belt, pulley and bearing life

- Time saving method as no cross-checking required

- Easier to use than conventional methods

- Supplied in a case or pouch

- No training required